GUAYAIBI (GUAH-YAH-BEE)

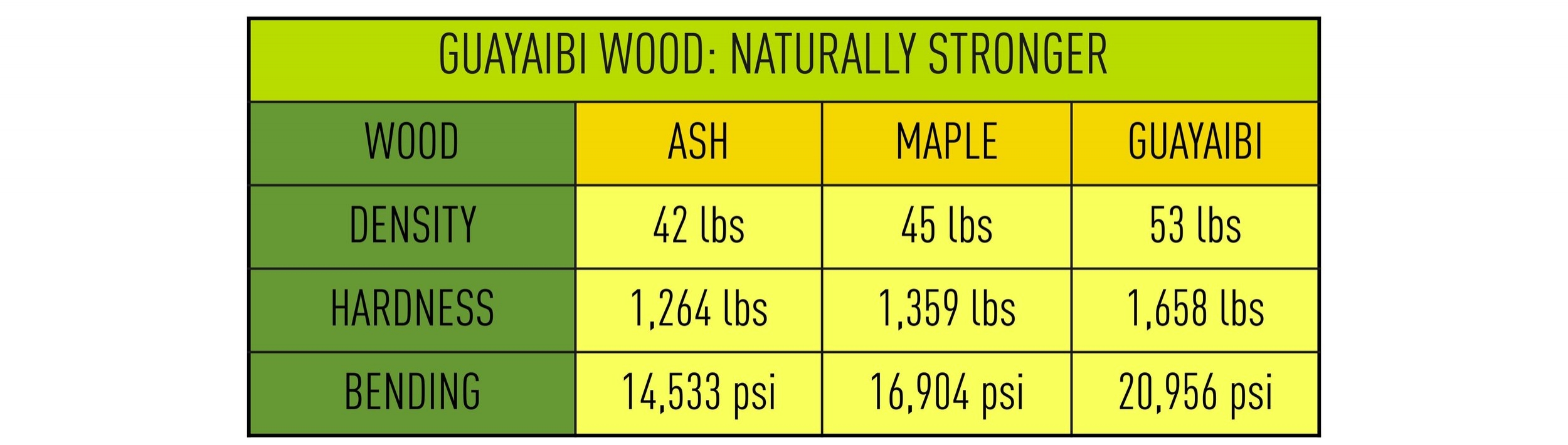

Compared to maple or ash, the Guayaibi wood grain is:

TIGHTER,DENSER and MORE FLEXIBLE

It has more

DURABILITY,IMPROVED SAFETY and UNBELIEVABLE POWER AND POP!

The quality of our hand-crafted bats is closely supervised in every step of the manufacturing process. Only the finest Guayaibi wood is carefully selected and extracted from the Argentinean sub-tropical forests by our experts, then dried, turned and painted in our private facilities using top technology to guarantee maximum quality.

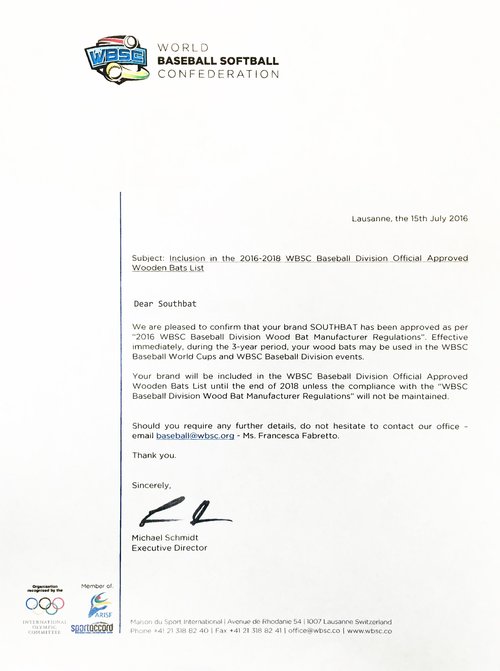

WBSC Approved and MLB approval in the works. BBCOR automatically approved when bat is solid 1-piece wood.

Click the image to enlarge...

Revolutionary Guayaibi wood bats. Flexibility test.